New outlook Excavator Bucket Bushing

Excavators are essential machines in construction, mining, and other heavy-duty applications. One of the critical components of an excavator is the bucket bushing, which significantly influences the machine's operational efficiency and durability. Traditional bushings, while functional, often lack in areas such as longevity, ease of maintenance, and aesthetic appeal. This paper outlines our factory's initiative to design and produce a new excavator bucket bushing that addresses these issues.

The first step in the development process was conducting a thorough market analysis to understand customer needs and identify existing shortcomings in current bushing designs. Feedback from end-users highlighted several key areas for improvement:

Durability: Customers demanded longer-lasting bushings that could withstand harsh working conditions without frequent replacements.

Maintenance: Ease of installation and maintenance was a critical requirement to reduce downtime and operational costs.

Aesthetics: There was an emerging demand for aesthetically pleasing components that align with the modern, high-tech appearance of new machinery.

Choosing the right material was fundamental to enhancing the durability and aesthetic appeal of the bushing. We considered several materials, including traditional steel, bronze alloys, and advanced composite materials. After extensive testing and evaluation, A forged steel was selected for the following reasons:

Wear Resistance: The alloy demonstrated superior resistance to wear and tear, extending the service life of the bushing.

Corrosion Resistance: Excellent resistance to corrosion ensured the bushing could perform reliably in various environmental conditions.

Machinability: The alloy allowed for precise machining, which was essential for achieving the desired aesthetic and functional features.

The design phase focused on incorporating advanced engineering techniques to improve both functionality and aesthetics. Key design elements included:

Enhanced Load Distribution: The bushing was designed to distribute loads more evenly, reducing stress concentrations and improving overall durability.

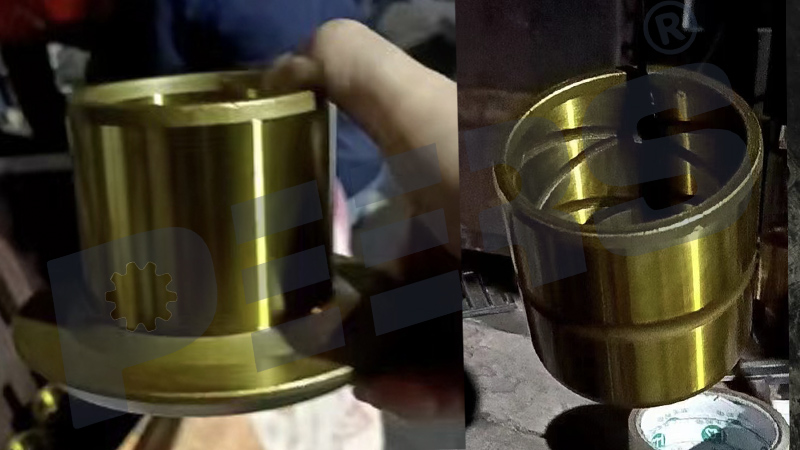

Integrated Lubrication Grooves: To enhance ease of maintenance, the design included integrated lubrication grooves that facilitate regular greasing and extend the life of the bushing.

Aesthetic Finishes: Attention was given to the surface finish and overall appearance. Polished surfaces and streamlined contours were implemented to provide a modern and high-tech look.

Finite Element Analysis (FEA) was employed to simulate the operational conditions of the bushing and predict its performance. The FEA model considered various factors such as:

Load Conditions: Simulating the different loads the bushing would encounter during typical excavator operations.

Wear Patterns: Predicting wear patterns to identify potential weak points and areas for reinforcement.

Thermal Effects: Analyzing the impact of temperature changes on material properties and bushing performance.

The FEA results confirmed that the new design offered significant improvements in load distribution and wear resistance compared to traditional bushings.

Prototyping and Testing

Following the design and simulation phase, prototypes were manufactured for physical testing. The testing phase included:

Laboratory Tests: Controlled laboratory tests were conducted to measure wear resistance, load capacity, and corrosion resistance.

Field Tests: Real-world testing on construction sites provided practical insights into the bushing's performance under actual working conditions.

The prototypes exhibited exceptional durability and maintained their aesthetic appeal even after extended use.

Customer Feedback and Iterative Improvement

Feedback from field tests was instrumental in refining the design. Iterative improvements were made based on customer input, further enhancing the ease of maintenance and overall performance.

Production and Quality Control

Once the final design was validated, the focus shifted to production. Advanced manufacturing techniques, including CNC machining and automated quality control processes, ensured that each bushes met stringent quality standards. Key aspects of quality control included:

Dimensional Accuracy: Ensuring precise dimensions to facilitate easy installation and optimal performance.

Surface Finish: Maintaining high-quality surface finishes to enhance aesthetic appeal and reduce friction.

Material Integrity: Regular testing of material properties to ensure consistency and reliability.

Environmental Considerations

In line with our factory's commitment to sustainability, the development process also considered environmental impacts. The selected bronze alloy was chosen for its recyclability, and manufacturing processes were optimized to minimize waste and energy consumption.

Conclusion

The development of the new aesthetic excavator bucket bushing represents a significant advancement in construction machinery components. Through meticulous market analysis, innovative design, and rigorous testing, we have created a bushing that not only meets the functional demands of modern excavators but also enhances their aesthetic appeal. This project underscores our factory's dedication to innovation, quality, and customer satisfaction.

Future Prospects

Looking ahead, we aim to continue refining our designs and exploring new materials and technologies to further improve the performance and appeal of our products. Customer feedback will remain a vital component of our R&D process, ensuring that we stay aligned with market needs and continue to lead the industry in innovation.

Acknowledgements

We would like to thank our engineering team, field testers, and customers for their invaluable contributions to this project. Their feedback and insights were crucial in developing a product that truly meets the needs of the market.