Bauma Show in Shanghai

December 10, 2024

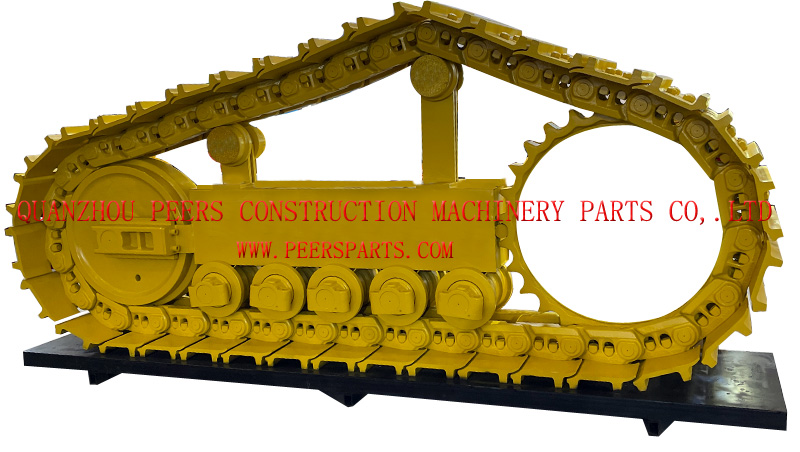

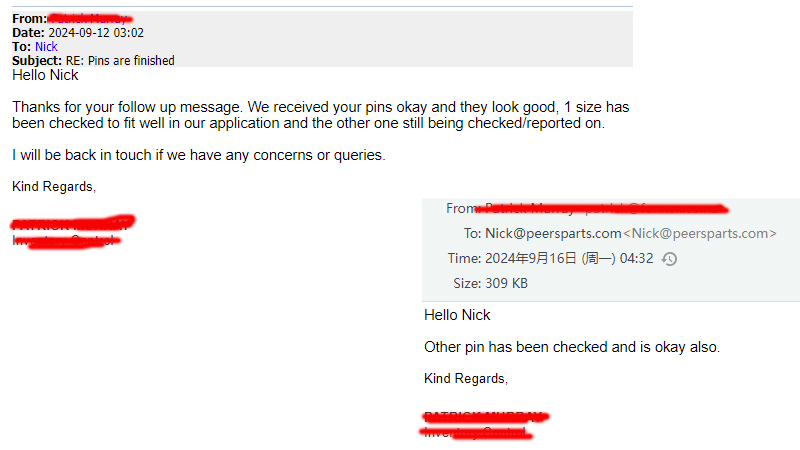

26th to 29th of Nov, our company successfully completed the participation in the shanghai Bauma exhibition, which was grandly held in Shang hai and attracted the attention of parts professionals from miner and construction, enterprise representatives and media from all over the world. in the industry, our company became one of the highlights of the exhibition with our innovative products, comprehensive solutions and outstanding team performance. It is a miner and construction machinery parts Exhibition. such as track roller, carrier roller, track chain, track shoes, track link, front idler roller, sprocket segment, track bolt, plow bolts, bucket pin, bucket bushing, pin track, bushings track, teeth pin, bucket teeth, bucket.... for mini excavator, bulldozer, excavator, crane crawler, loader, and skid loader also. During this exhibition, our company focused on displaying the newly developed and highest quality products, The booth design is unique and intuitively presents the core functions and application scenarios of the product, attracting many visitors to stop and experience. A visitor from UK just said, “Your company's products are very good at quality, which is the solution we have been looking for.” During the exhibition, our company also conveyed the unique advantages and use value of our products to customers through on-site demonstrations and interactive sessions. A number of customers expressed their intention of cooperation on the spot, opening up new opportunities for the company's future business development. High-level sharing of cutting-edge views, in-depth analysis of industry trends In addition, our company also participated in a number of round-table discussions, discussing exclusiving agent with industry partner. Through these exchanges, we not only deepened our insight into industry dynamics, but also provided important inspiration for future product development. During the exhibition, our company reached strategic cooperation intentions with a number of well-known enterprises covering mainframe equipment factory, and the establishment of these partnerships will inject new vitality into our global business layout. The successful completion of this exhibition not only demonstrated our strong technical strength and market competitiveness, but also accumulated valuable resources and experience for future development. We are well aware that this is just a new starting point. In the future, our company will continue to uphold the purpose of “Provide the first class service, establish the first class quality products”, and constantly promote technological progress and industry development, to provide customers with more high-quality solutions. We would like to express our heartfelt thanks to all our customers, partners and industry colleagues who have supported and paid attention to us. We look forward to cooperate with you!

View More