Launched new product of Bulldozer Block Series

May 12, 2024

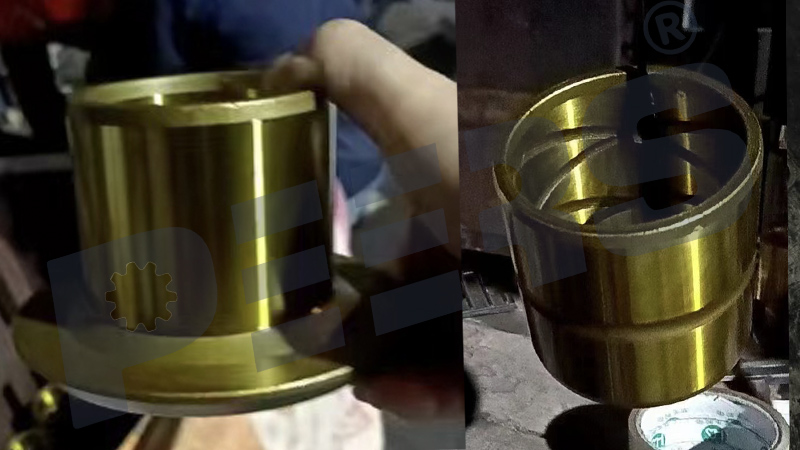

In the dynamic landscape of construction and heavy machinery, innovation is not just a buzzword; it’s the driving force behind progress. Today, we are thrilled to announce the launch of our latest breakthrough in the field of construction equipment - our all-new Bulldozer Block series! After meticulous research, development, and rigorous testing, our engineering team has successfully crafted a range of bulldozer blocks that are set to redefine industry standards. These blocks represent a fusion of cutting-edge technology, precision engineering, and robust design, offering unparalleled performance and reliability on the construction site. What sets our Bulldozer Block series apart is its unmatched durability and versatility. Engineered to withstand the toughest working conditions, these blocks are built to last, ensuring maximum productivity and efficiency for your construction projects. Whether you’re clearing land, grading roads, or pushing materials, our bulldozer blocks deliver optimal performance, day in and day out. But innovation doesn’t stop at functionality. Our Bulldozer Block series also boasts ergonomic design features aimed at enhancing operator comfort and safety. From intuitive controls to enhanced visibility, every aspect of these blocks is designed with the operator in mind, ensuring a smooth and comfortable operation even during the most demanding tasks. Furthermore, our commitment to sustainability is reflected in the materials and manufacturing processes of our Bulldozer Block series. We prioritize eco-friendly materials and efficient production methods to minimize environmental impact without compromising on quality or performance. As we unveil our Bulldozer Block series to the market, we are also excited to offer a range of promotional offers and support services to our valued customers. From special financing options to personalized training programs, we are dedicated to ensuring that our customers have everything they need to succeed with our products. We invite you to join us in this momentous occasion as we usher in a new era of construction excellence with our Bulldozer Block series. Stay tuned for more updates and details on availability by visiting our official website or contacting our customer service hotline. Together, let’s build the future of construction, one block at a time! Here are some block part no. 9W-7882, 17M-30-52140, 306-9445, 306-6441, 131-1650, 283-5747, 283-5748, 306-9453, 306-9452, 306-9447 The launch of our Bulldozer Block series is not just a milestone for our factory; it’s a testament to our unwavering commitment to innovation, quality, and customer satisfaction. As we continue to push the boundaries of what’s possible in construction equipment, we extend our heartfelt thanks to our customers for their ongoing support and trust. We look forward to serving you with more groundbreaking products and solutions in the years to come. Thank you for being part of our journey towards a brighter, more sust...

View More