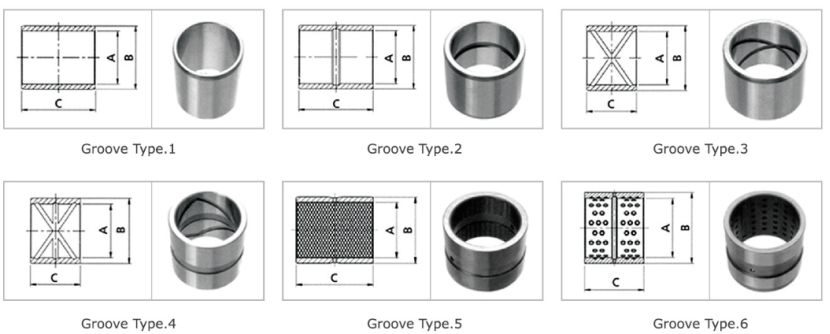

The type of bucket bushings on the market:

The Importance of Bucket Bushings in excavator and mining machine

The significance of bucket bushings extends beyond their basic function. They are essential for several reasons:

No.1 it is safety:

Properly functioning bucket bushings ensure that machinery operates safely. They help prevent accidental dislodgment of pins, which can lead to catastrophic failures.

No. 2. It is performance:

With adequate lubrication and minimal friction, bucket bushing enhance the performance of construction machinery, allowing for smoother and more controlled movements.

No. 3. It is longevity:

By reducing metal-to-metal contact, excavator bucket bushes prolong the lifespan of both the bucket and the machinery itself, translating to cost savings over time.

How to prolong bushings’ life.

To ensure optimal performance of excavator bucket bushings, regular maintenance is essential. Here are some best practices:

Regular Inspections: Periodically inspect bucket bushings for signs of wear, such as cracks or deformation. early detection can prevent further damage.

2. Lubrication: Ensure that excavator bushes are adequately lubricated. This reduces friction and enhances performance. use high-quality lubricants suitable for the operating environment.

3. Cleaning: Keep bushings clean to prevent dirt and debris from affecting their performance. Regular cleaning prevents the buildup of contaminants that can cause premature wear.

4. Replacement: Know when to replace bucket bushings. If they show significant wear or damage, replace them promptly to maintain the efficiency of the machinery.

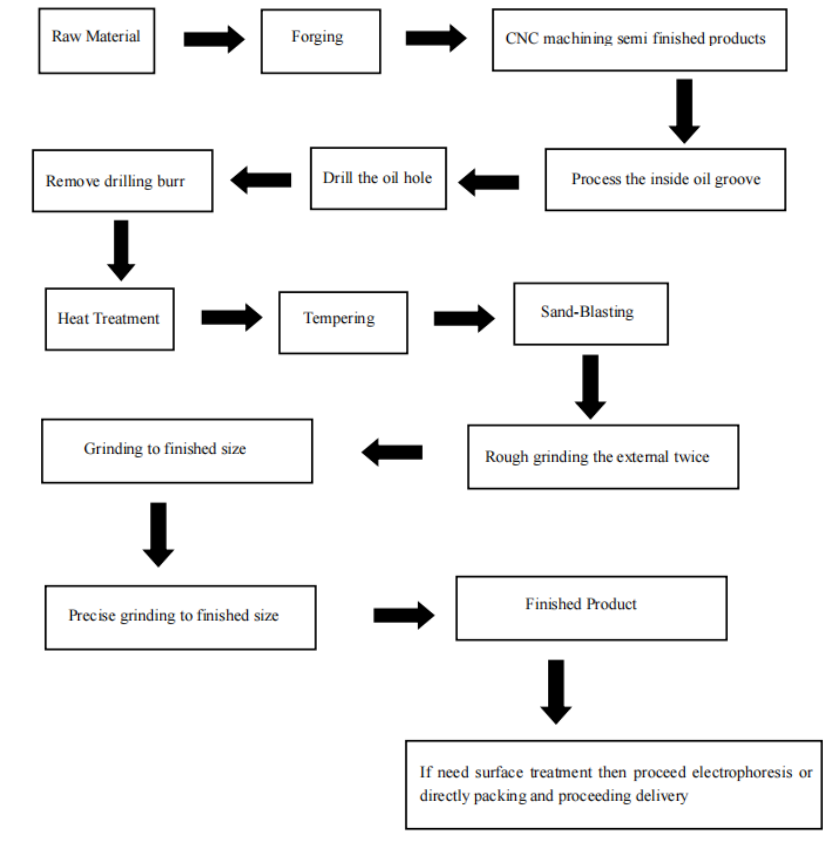

Quality bushes coming out as below process:

Avoided below factor when you choose the bucket bushings.

Despite their durability, bucket bushings can encounter several common issues:

a. Excessive Wear: If bushings wear down too quickly, it may indicate improper lubrication, incorrect installation, or using low-quality bushings. Addressing the root cause is essential to prevent recurrence.

b. Misalignment: Misaligned bucket bushings can lead to uneven wear and poor performance. Regularly check alignment during maintenance checks.

c. Foreign Object Damage: Debris can enter the bushing area, leading to scratches and damage. Implementing a good cleaning routine can minimize this risk.

Choosing right bushes for your excavator or loader.

Selecting the correct bucket bushings is crucial for maximizing efficiency. Here are some factors to consider:

Material: Choose materials based on the specific application. Steel bushings are durable but may wear faster in high-friction environments, while composite materials may offer better longevity.

Heat treatment: Regular heat treatment can ensure the hardness and toughness.

3. Size and Fit: Ensure that the bushings fit correctly with the bucket pins. Poor-fitting bushings can lead to increased wear and operational issues.

4. Load Capacity: Consider the load capacity of the bushings. Ensure they can handle the operational stresses of your machinery.